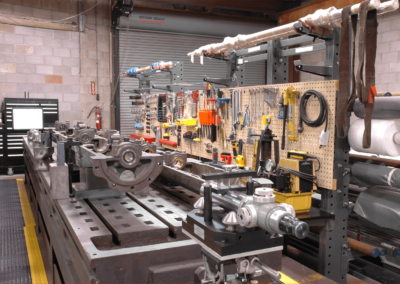

Well-organized tools on the shop floor at Kams, Inc.

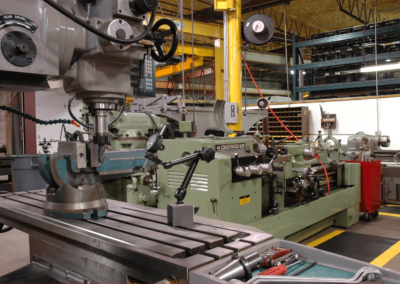

Milling a camshaft at Kams, Inc.

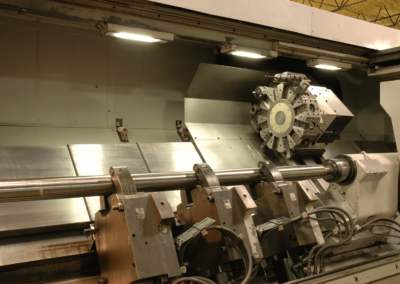

A CNC lathe used for manufacturing large shafts and camshafts

Kams, Inc. can check Ingersoll-Rand KVS & KVG compressor cam housing alignment using a precision optical telescope. If any main bearing locations are out of tolerance, they can be repaired in-house by line boring.

Cam lobes and other parts that are going to be heat treated must be painted in this are.

Kams, Inc. has a large inventory of cam lobes, muffs, and sections for many different industrial engines.

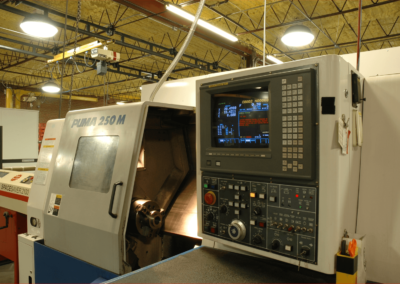

One of the CNC lathes used in the cam and follower manufacturing process

Inventory of cam lobes for large industrial engines

With our automated bandsaw we can quickly cut raw material into the appropriate size for manufacturing camshafts, cam lobes, cam sections, cam follower rollers, pins, and other parts.

Assembly area for roller lifters and camshaft followers

Kams, Inc. has the capability to manufacture cam shafts up to 22 ft long on this machine

Roller cam followers are manufactured and rebuilt

With barfeed capability we can quickly produce rollers and pins for cam followers.

Camshaft Shipping Department on Shop Floor at Kams, Inc.

Our manual machining department includes equipment for line-boring Ingersoll-Rand cam housings for KVG and KVS compressors.

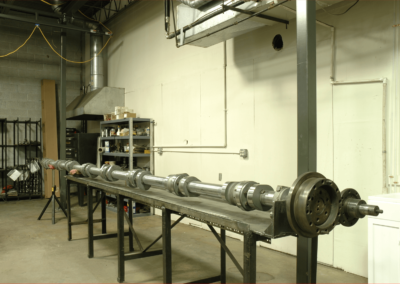

Worthington UTC 8-cylinder cam shaft with adjustable fuel lobes. This camshaft was manufactured and assembled by Kams, Inc.

All cam followers and roller lifters are checked for proper clearances and operation

Cam grinders in the camshaft remanufacturing and regrinding area

Kams, Inc. operates a full line of manual lathes and mills which are used for various operations in the camshaft manufacturing process

The Magna-flux system is used to check for hairline cracks during the manufacturing and rebuilding processes.

Camshaft Grinding Department at Kams, Inc.

Title

This CNC mill is used in the manufacture of cam lobes, cam sections, and cam muffs.

Camshafts, lobes, and muffs are cleaned here after heat treatment by bead and shot blasting

Shafts and cam sections are straightened on this straightening press. This photo shows an Ingersoll-Rand KVG camshaft being straightened after the cam muffs have been pinned to the shaft.

Cam and Lifter Shipping Area at Kams, Inc.

CNC mill used in the manufacture of cam lobes, cam sections, and cam muffs

Ingersoll-Rand KVG Camshaft Housing Rebuild by Kams, Inc.

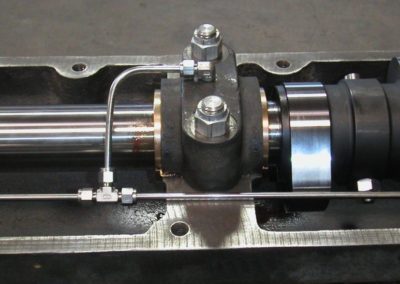

Detail of main bearing on Ingersoll-Rand KVG cam housing. Kams, Inc. regularly rebuilds these camshaft assemblies, including custom stainless-steel oil lines.